Services

During our existence, AXPEL MADE became a strong partner for many small, medium and large companies and the satisfaction of our customers is confirmed by their long-term cooperation with us.

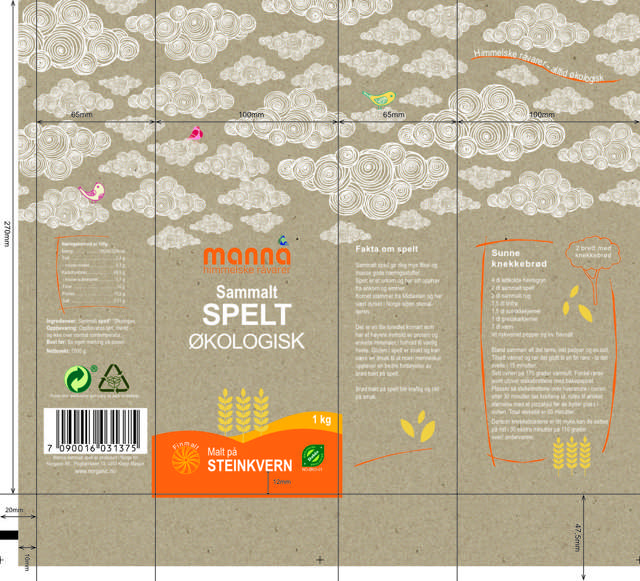

Custom design of your packaging product

We will engineer a custom solution and design to best fit your unique filling and shipping operations and customer usage requirements.

We will first choose the most suitable material, from both a functional and an aesthetic perspective, based on the specifications of the product to be packaged. We will help you choose most advantageous printing technology for the bag; we will leverage our industry experience during design creation, and thanks to our knowledge of printing technology we will send comments to graphic artists so that the resulting print is of the highest quality, yet economical.

According to the type of your packing machine, we will adapt the composition, dimensions and perforation of the bags so that everything runs the way it should during the filling production process.

Printing

Flexographic printing

Print up to 8 colours in HD flexo design with the option of applying flexo gloss. The colours we use for printing are water soluble which means they are not harmful to health and are designed for direct contact with foodstuffs. The quality of the print is guaranteed not just by experienced printers but also by colours and a high paper quality. Modern printing technology enables high control of the quality of the print even at full speed.

Offset printing

Print up to 6 colours using EB (Electron Beam) and 2 roto colours. EB colours are dried by an electron beam which compared to UV drying is more efficient and guarantees zero migration of harmful substances. The EB offset printing technology was developed especially for the food and pharmaceutical industries.

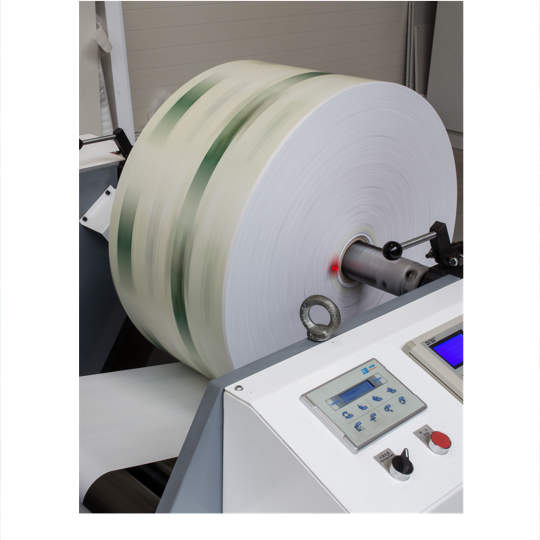

Roll to roll printing

Our modern equipment enables us to print in a very high quality whether it's flexographic or EB offset printing. The high performance of our printers guarantees sufficient production capacity which is why we can supply large customers with printed paper in rolls. We also offer the option of cutting the rolls into smaller widths.

Storage

Storage for your paper bag products is available in our state-of-the-art storage facilities, all of which comply with the most stringent hygienic standarts. These complementary storage services enhance our ability to fulfill repeat customer orders within days from the date of their purchase order. The installed pallet tracking system based on RFID chips and scanners provides for absolute transparency and control of product movement within our facilities. And, the dry loading docks facilitate transfer of the products from storage to trucks and shipping containers without the risk of contamination from external environment. This feature is especially valuable for transport of packaging designed for food content.

Packaging products

A paper bag closed at both ends and featuring a valve/sleeve designed for high-speed filling. Customized to allow for optimal filling performance, handling, paletization, and storage.

A paper bag with a pasted, satchel style bottom, no gussets, and available with or without liner. Open mouth allows for easy filling without need for expensive filling equipment.

Self Opening Square Bag

SOS | PSOS

A paper bag with a flat, square bottom and gussets. The free-standing construction allows for easy filling and good stability on shipping pallets and brings practical value for end-users.

Pinch Bottom Open Mouth Bag

PBOM | PINCH BAG

A multiwall paper bag, glued and folded at one end with a pre-applied coating of hot melt adhesive applied at the other end to provide an efficient sift-proof closure.

These bags are the environmentally-friedly solution for carrying products from the point of sale to the place of usage. Typically adorned with company logos, slogans, and photos to function as walking advertisements for the company.

A printed substrate used for either running high speed form, fill & seal equipment supplying predominantly Consumer Markets or for wrapping products at the point of sale or in shipping operations.